Industrial / Manufacturing

Facility Planning

Concept To Completion

Driving Projects with

your Vision in Mind

Considering a facility addition? Maybe a new building? Consolidating multiple facilities? Integrating new equipment?

If you are not sure where to start, or whether you have the budget, begin with a comprehensive Master Planning Study. Our extensive portfolio of 5,000+ projects of all sizes and complexities includes industrial, manufacturing, pharmaceutical, and food facilities. This makes Lamb the right partner to assess the best direction for your project.

Where to Start

Careful, Considered Planning is the Foundation

Lamb strongly believes in this first step — we accurately identify your vision and unique needs and deliver a design that improves your facilities’ operational excellence.

A planning study creates the roadmap for the Detail Design and Construction phases, ensuring your project is on time and on budget. We not only guide you through today’s facility challenges, we provide you with a comprehensive Master Plan to drive your future.

Build your case with the tools and documentation to gain leadership support.

Step 01

Conduct Surveys and Interviews

Step 02

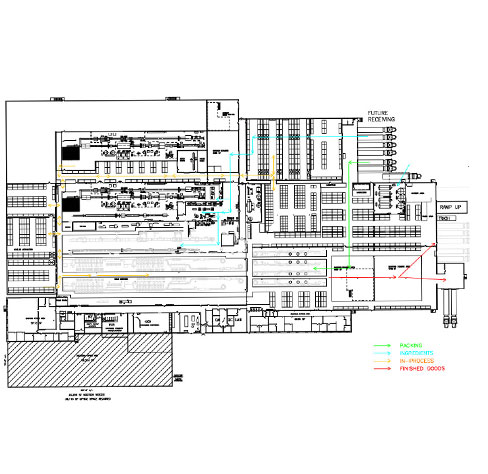

Develop Conceptual Options

Step 03

Finalize Concept & Layout

Step 04

Generate Order of Magnitude Budget & Schedule

Step 05

Develop Executive Report & Presentation

One Team

Reliable Project Partners

Collaboration. You know your facility. Our experts know projects. When our in-house Facilities Planners, Architects, and multidisciplinary Engineers become an extension of your team, together we customize a project that succeeds.

Facility Planning starts with Lamb’s team:

Conducting in-depth interview sessions of your objectives, functionality, and space programming requirements to ensure your vision aligns with your budget and timeline.

Understanding new equipment integration to optimize workflow.

Benchmarking against industry standards and identifying gaps in regulatory and environmental compliance, security, etc.

Diving into your and your employees’ day-to-day operational and safety needs, including workflow and mechanical, electrical and plumbing (MEP) systems.

Next Steps

Once complete, we deliver concept plans for your headquarters, facility or project space, an outline design narrative — including layouts for equipment, MEP systems, and adjacent spaces, an order of- magnitude budget estimate, and preliminary milestone schedule.

Client communication is key. With Lamb’s Architects and Engineers all under one roof, it’s seamless. We work together, from start to finish, to optimize your state-of-the-art facility.

See What’s Possible

Give your industrial, manufacturing, warehouse, or laboratory project the strongest foundation, so you realize a meaningful return on your facility investment.

Plan for the right solution, from the start.